M

Muna da nau'i-slot pusching, matsananciyar bugun zuciya, da kuma saurin haɗe-hanzari suna dacewa da bukatun Motsa don biyan bukatun motocin daban-daban da rotors. Kusan 90% na muLAME an tsara su daga zane. A lokacin tsarin ƙirar ƙirar, ƙwararrun masu zanenmu zai sa su gabatar da wasu shawarwari masu tsari don kyautata masu cinikin abokan ciniki.

Samfurori yin

Zamu iya haduwa da girman girma da fasaha na buƙatun samfuran layin Layin.

A

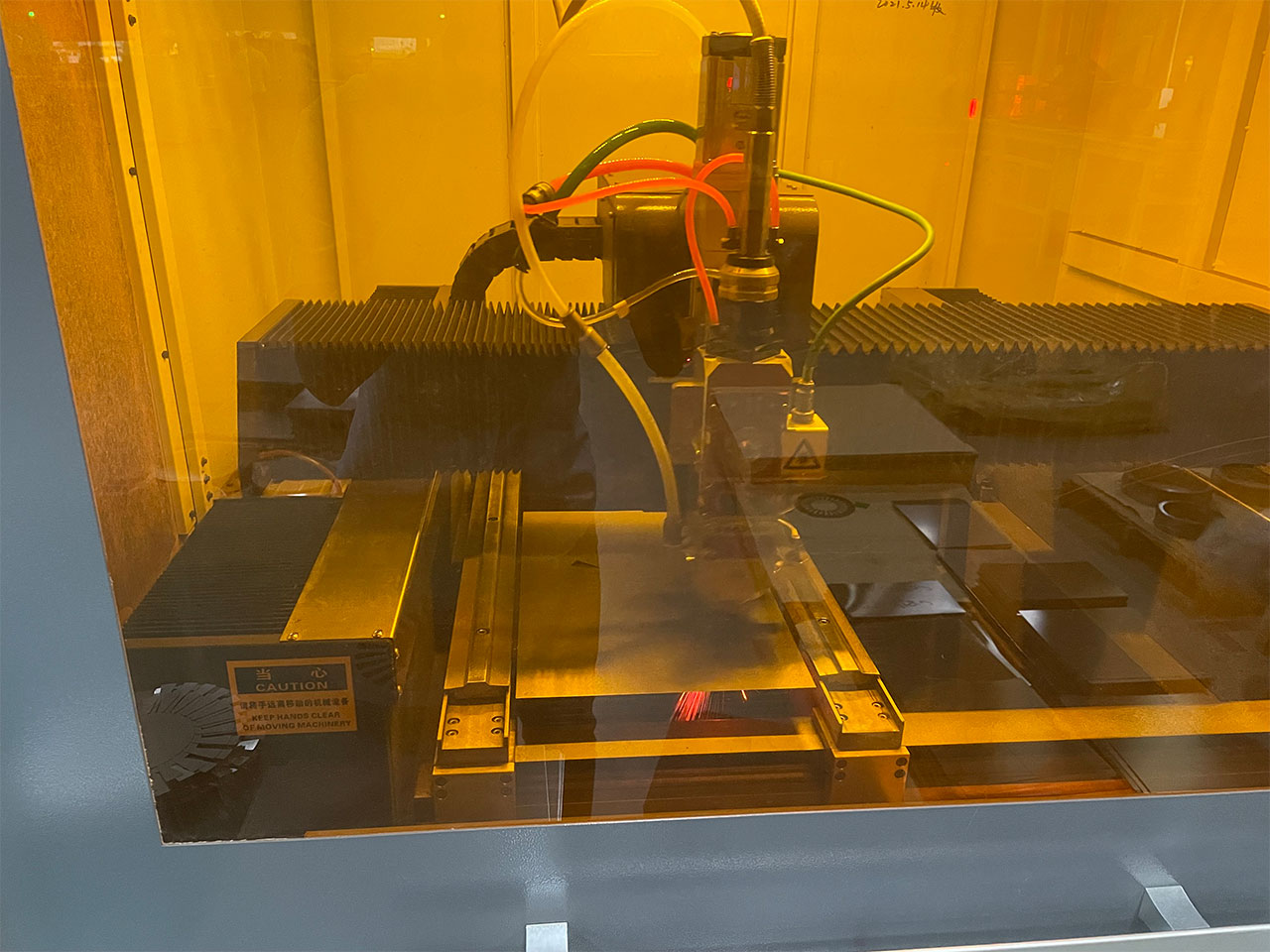

Yankan Laser

C

High Speed Yanke

B

Yankan Middle

D

Yankewa Mai Girma Mai Girma (Muka shigo da injin samfurin SEBU daga Japan)

Staming

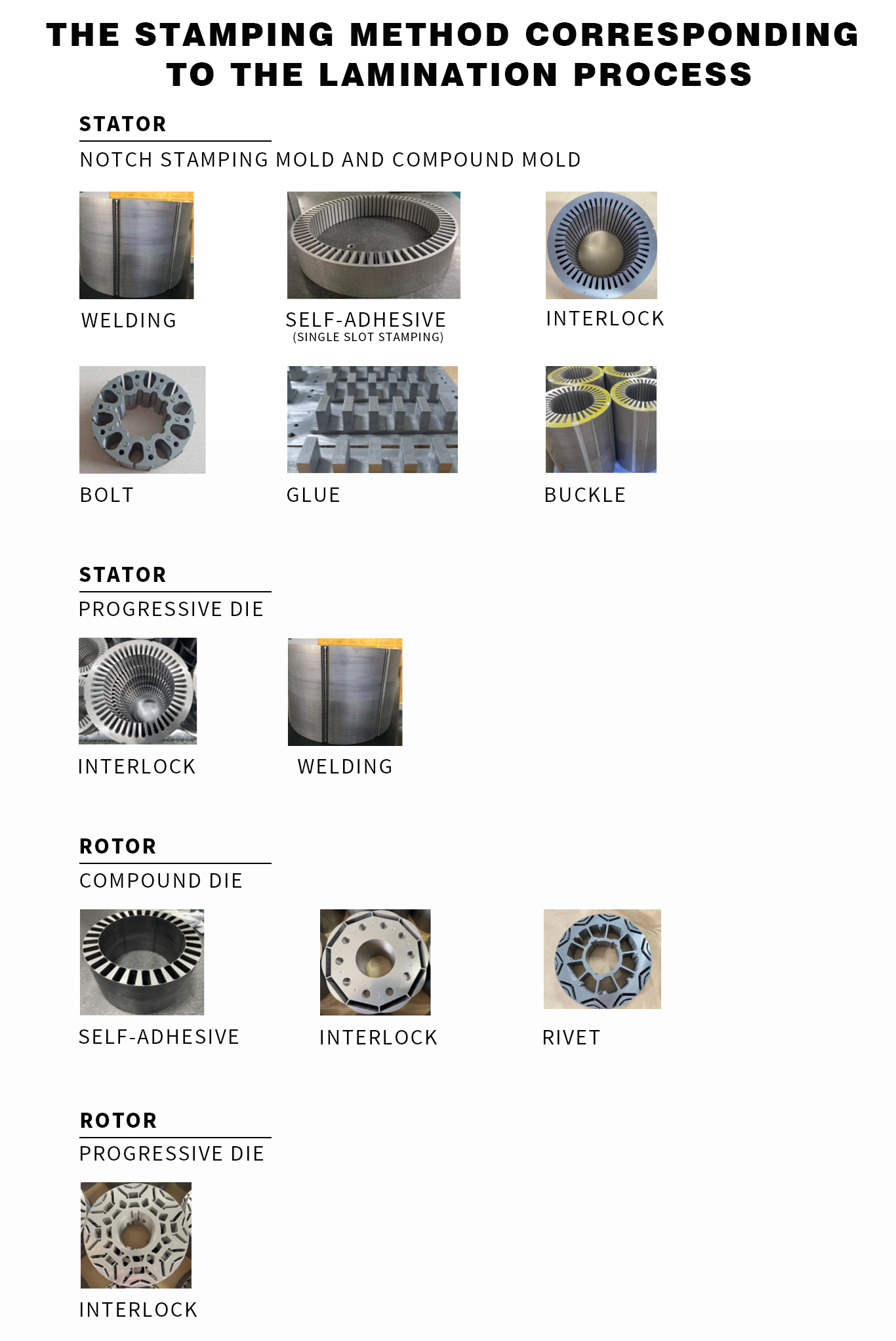

Muna da nau'ikan zaɓuɓɓuka daban-daban don saduwa da buƙatun siye daban-daban.

Single Slot Stamping

Ayyukan: 10t-16t

Tambura

Ayyukan: 40t-550T

M(Babban gudu)Staming

Ayyukan: 630T, 550t, 315t (Schuler),300t (aida),160t, 120t, 80t (nidec)

Taron Stamping & Amfani

↓

Ada ADA, 'Nidec daga Japan,wanda bari mu a cikinLAMEmasana'antar masana'antar Lever yanzu.

B.ACACE Batch of of of 0.1mm farin ciki silicon karfe da 0.03m murya silicon ba -hoy.

C.The Single Slet Slot na iya jefa hatimi Od2000m.

Single Slot Stamping

Kayan aiki: Notch Tramping mutu

Yanke takardar silicon zuwa girman da ake buƙata, kuma kowane yanki daga cikin sa ake yi daban-daban cikin sifar da ake buƙata. Single slot slot ne mafi dacewa hanyar da ta dace ga stator lamatings tare da mafi girma na diamita da kuma yawan samfurori.

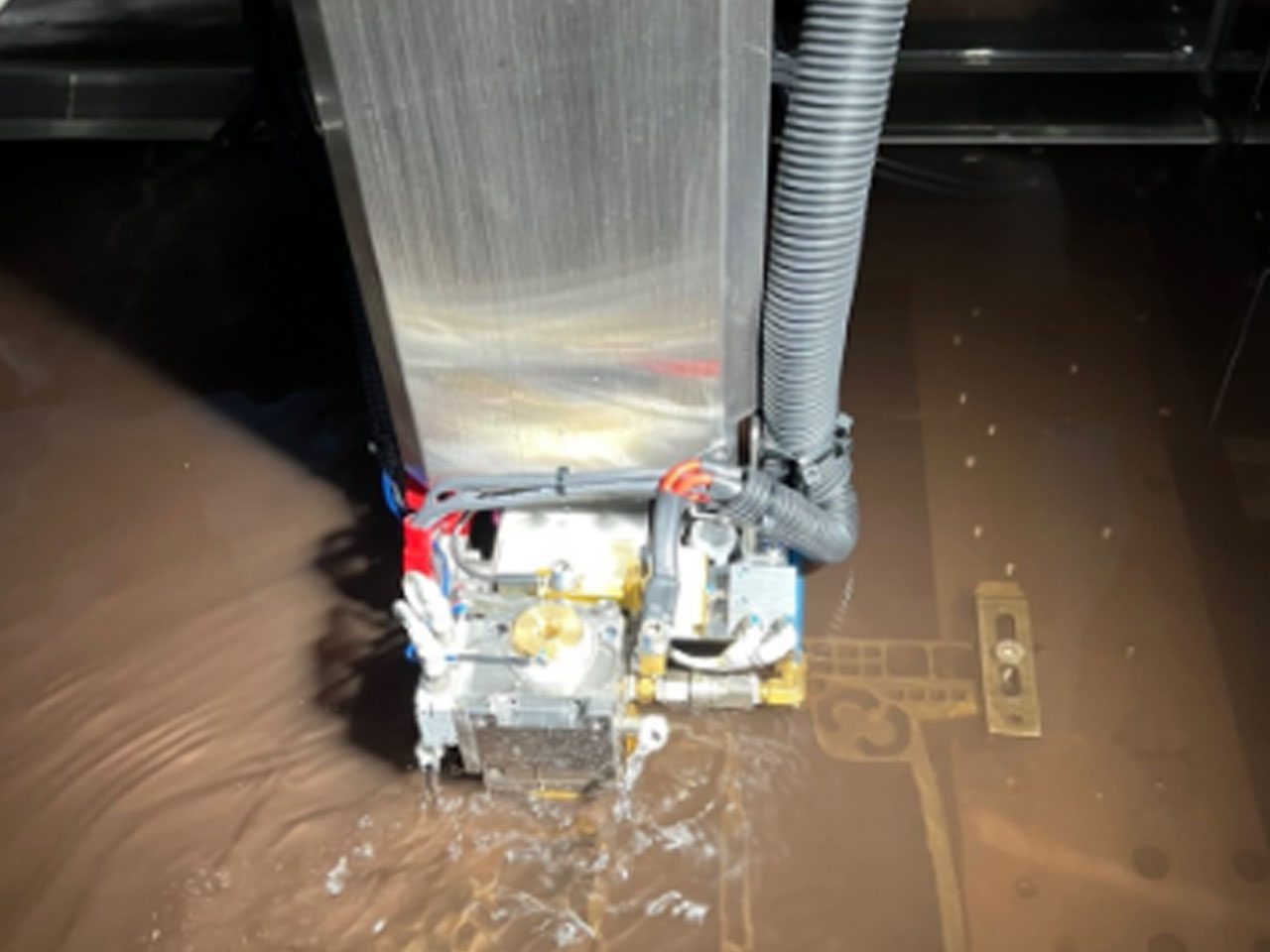

Tambura

Kayan aiki: Hutu mutu

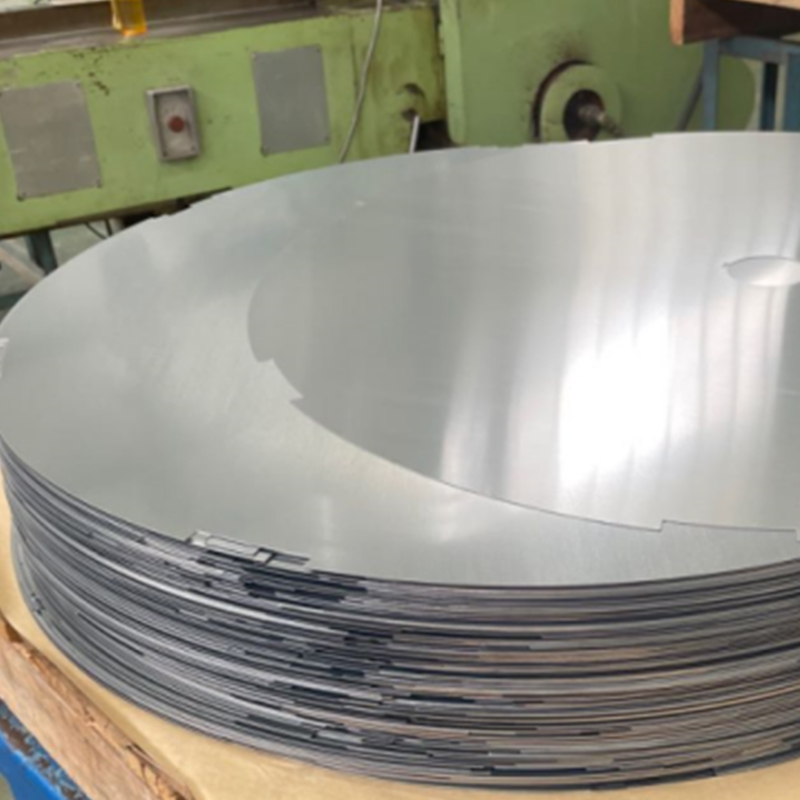

Sayi m silicon karfe gwargwadon girman samfurin da ake buƙata, canja wurin kayan manema labarai, sannan kuma ya samar da Lamation Rotination, duka Stator Lamination da Rotor Lamination da Rotor Lamination da Rotor Lamination da Rotor Lamination da Rotor Lamination da Rotor Lamination da Rotor Lamination. Akwai hanyoyin ciyar da abinci guda biyu, shine don amfani da wafer zagaye da wasu ƙananan motar, wanda ba shi da inganci, amma zai iya ajiye farashin kayan; Sauran yana ci gaba da ciyar da tube, tare da babban aiki.we zai bincika yanayin wafer stocke, sannan kuma suna lissafin mafi kyawun farashi don yin kwangila don mai motsa jiki da murkushe. Bugu da kari, kamfaninmu yana da kayan kira akan son kai ta hanyar da aka yi amfani da shi, wanda ya rage farashin tabbataccen abin hawa a cikin sinadarin mutu.

Takaddun ci gaba

Kayan aiki: cigaban mutu

Ana kuma kiran wannan moldwararrun mold. Bambancin ƙirar mold, yana iya amfani da abin da ya dace da abin da ya dace don ciyarwa, kammala tambarin da keɓaɓɓen tari kai tsaye don samar da stator da rotor tari.

Akwai nau'ikan son kai guda biyu. Isayan shine Madaukin Madaukin kai tsaye don ƙaramin girman ma'aunin layin ruwa, wanda yana da buƙatun fasaha. A lacks baya buƙatar matsawa sau biyu a kan kayan aikin kayan aiki.The ɗayan shine maɓallin dubawar kai na tilas, wanda ke buƙatar matsin lamba na sakandare don tabbatar da sauri.

Iska mai iska

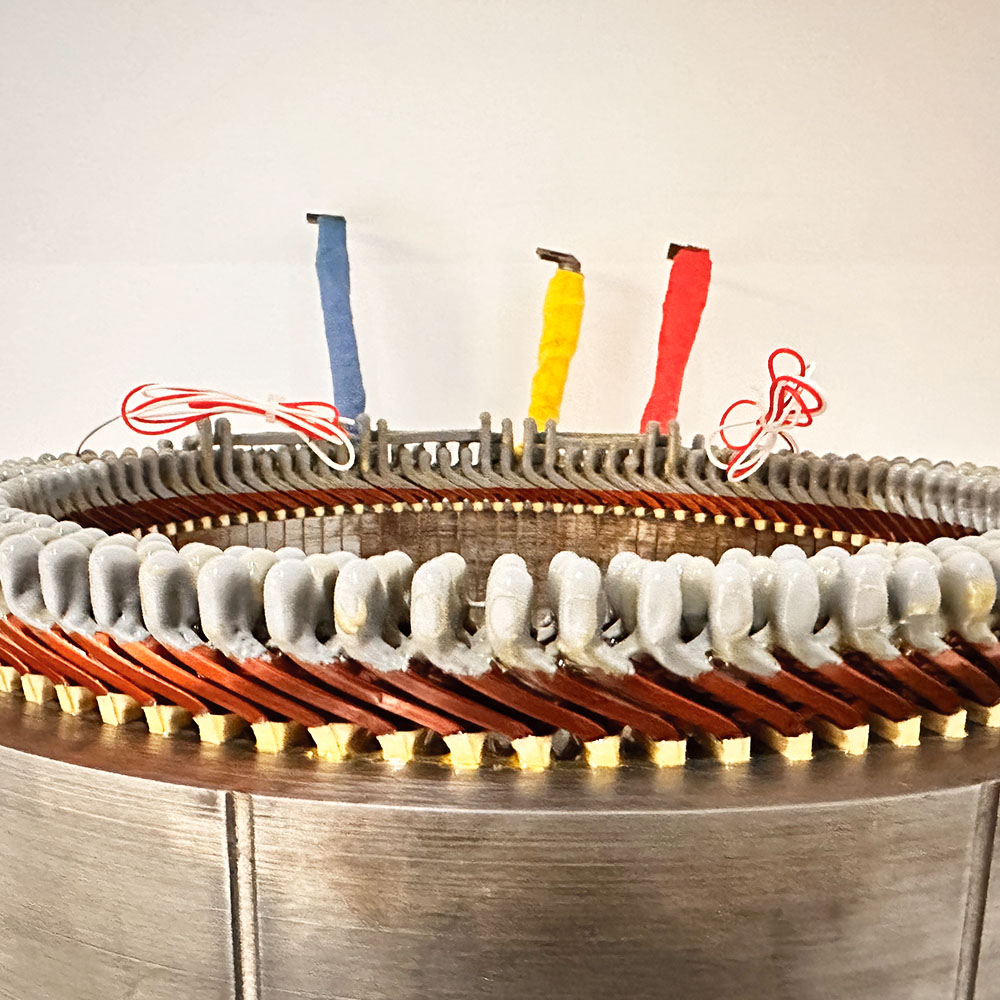

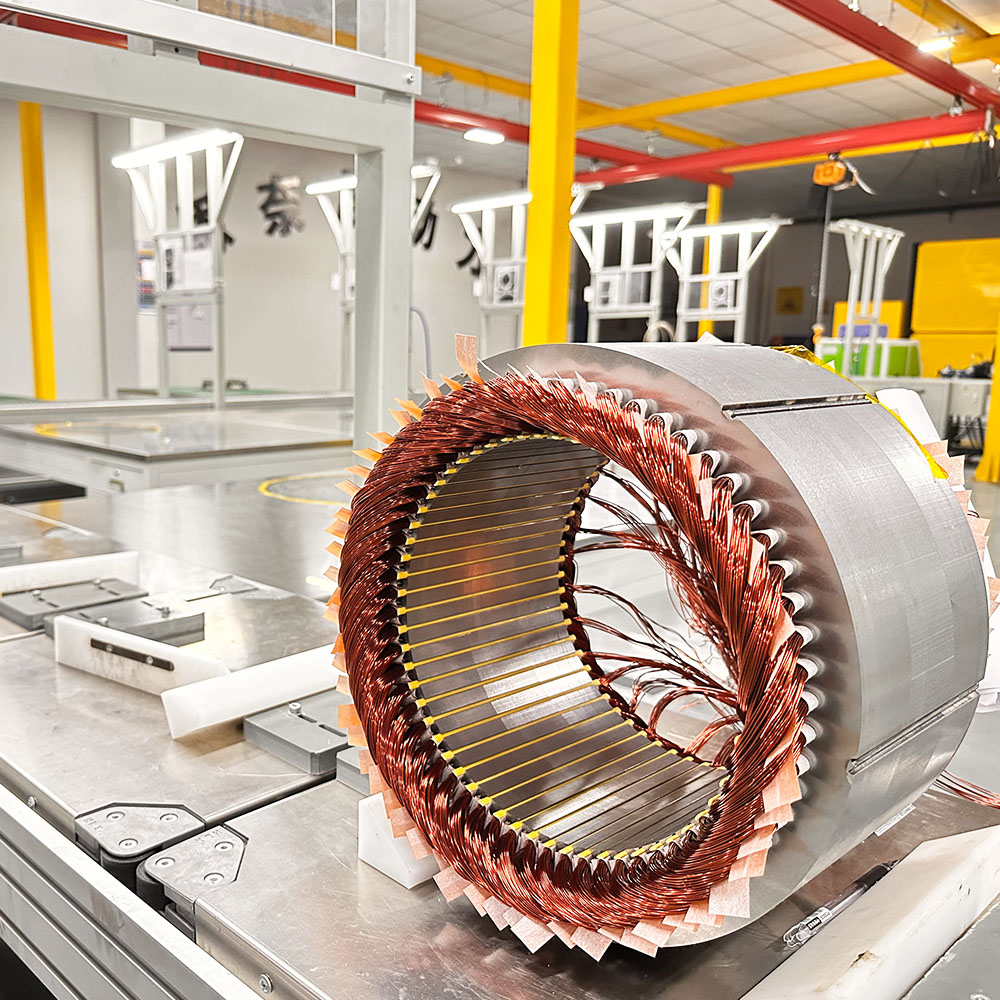

Muna samar da zagaye waya da iska mai iska, duka ƙananan girma a cikin tsarin samfurin iska shine 15-8. A halin yadudduka na ƙayyadadden samfurin ba su dace ba. Na asali 5-50 sits / rana.

Tura

Za a sanya Lamation cikin tsoratar da su ta hanyar Rivet, a ciki, waldi, manne, da sauransu, manne, tsayin daka, tsayin daka zai yi yawa.

Rivet

An yi amfani da kullun rivet Stacking gaba ɗaya don Rotor, akwai da kai rivet da lebur rivet.

Walda

Ana amfani da Welding Stacking don Stator Laminations, akwai walying da Tig Welding.

Gulu

Fenti manne a kowane babban abin hawa da kuma sanya su tare.

Taɓaɓɓe

Sanya abubuwan Interlock yayin buga ido, za a yi ta daki-kai ga stores tare da waɗannan abubuwan. Canji zai iya zama kusa da murabba'i ko zagaye. Cigaban Cigaban Duk Amfani da Shiga ciki don adana stator da Kudin Rotor tari da lokaci.

Da kai

Abu: b35a300-z / b55a400-z

Abubuwan suna da kayan rufi a saman sa, zai narke kuma ya haɗa da haɗa kowane mai jujjuyawa ɗaya da stator tunani tare yayin dumama. Hankalin kai zai sa samfuran kaya da kuma mafi ƙarfi.

Maƙulli

An yi amfani da bolt ɗin gaba ɗaya don stator Lamings tare da mafi girman diamita.

Zare

Ana amfani da bugun jini don stator lomination, akwai madaidaiciya ko ƙwanƙwasa.

Rangaɗi

Kayan aikinmu sun hada da masu aiwatarwa, daidaitawa, zane-zane na karfi, tsariyar murhun baƙin ƙarfe, da sauransu, da cmm suna da alamomi, hexagon, da kuma wenzel brands.

An rarraba bincike zuwa yada labarai na farko, binciken kansa, dubawa na Patrolation da bincike na ƙarshe. Duk abin da Hanyar Statping ita ce, fewan farko da na farko na ɓoyayyen hawan baya da kuma rotor suna buƙatar aikawa zuwa ɗakin dubawa, da samarwa da yawa ana iya aiwatarwa ne kawai bayan an zartar da binciken.

Shiryawa

Dangane da bukatun abokin ciniki, masu ƙididdig din suna cike da kayan ƙarfe, akwatunan ƙasa, kwalaye na katako, da takarda na ciki ya haɗa da takarda na ciki, da sauransu.

Lokacin da ƙwararrun ƙwararrun motoci ya ƙare ko kuma maimaitawa da mai jujjuyawa, za mu rarrabe su da soso da shirya cikin lamuran da ba a fitarwa ba.